30+ Ways To Conquer Supplier Risk & Performance Management

This past summer, I was visiting some family for a few weeks time in the States.

Every time I stay somewhere for an extended period of time — regardless if it’s a hotel/AirBnB or being a guest at someone’s flat — I like to unpack my clothes in the wardrobe. Otherwise, one might as well just walk around with a sign on their back that say’s ‘I LOVE WRINKLY CLOTHING’.

But, I digress.

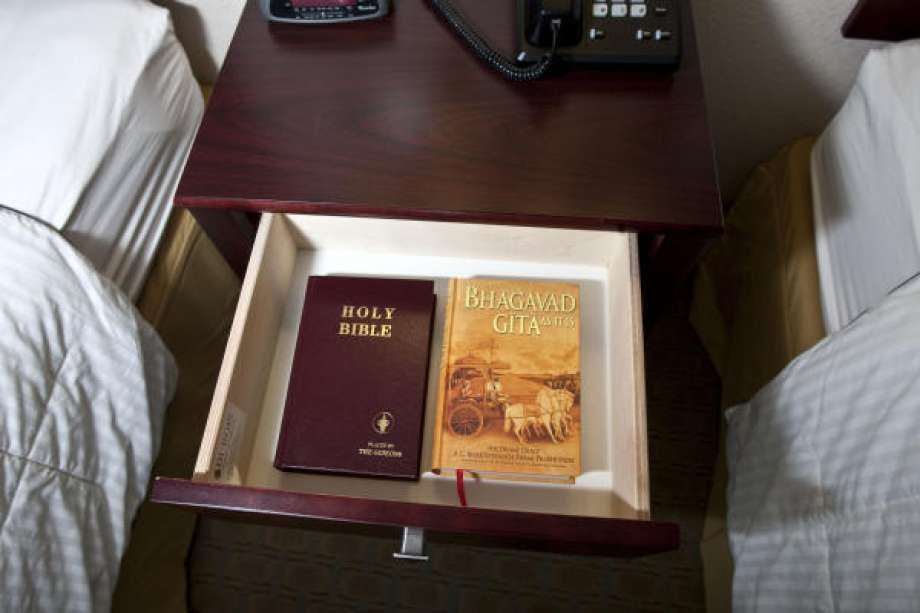

If you’ve never stayed in an American hotel chain/rummaged through the shelving, then you may not be aware that almost every bedside table has a copy of the ‘Holy Bible’ in it.

Why?

Simple… The Holy Bible is the numbered one read, and purchased, book in the world, and studies in 2015 have shown that nearly 70% of Americans identify as Christians (Pew Center 2015). A bible being in the bedside table is nothing more than a gesture of hospitality by hotel chains, looking to please their largest demographic.

But, what does any of this have to do with Kodiak Hub, Supplier Risk and Performance, or you as a reader!?

Well, some of you have been along for this ride for the last 2 and a half years, opening the shelves of the Kodiak Community Blog almost every week to find a new bit of material to peruse, but no Bible. I thank you for your loyalty and commitment. And, to those of you who are reading for the first time, thank you as well.

But, this post isn’t an acceptance speech at the Grammys. I’m not going to thank my second-grade teacher or my Grandma, but I am going to show my appreciation for you as a reader.

70% of the people reading this blog are Procurement professionals. It’s finally time show my hospitality, open the bedside table and provide you with the Holy Bible, Quran, Old Testament, Veda, Torah, and Tripitaka, or whichever piece of literature you utilize as a tool for worship; all in one post.

Here are 30+ Areas you should look to Assess and Evaluate Supplier Risk and Performance!

Where to Start?

As our CEO and Founder, Malin Schmidt, typically says about business processes and operations, “We need to build the wardrobe before we can start hanging our clothes.”

So, I would like to provide you with a framework of three very important processes that your Procurement, Sourcing, Quality and Sustainability teams can look to align upon, and implement as a precursor to evaluating supplier risk and performance.

Strategies to Manage Supplier Risk & Performance

It’s important to have a systematic framework for the following:

Supplier Risk Assessment (Self-Assessment)

Completing a supplier risk assessment is the first step for ensuring supplier compliance before, during or after entering a collaboration agreement.

This is your procurement team’s opportunity to mitigate risk, assess suppliers in various risk parameters, and gain an insight into their existing business practices. A common practice to complete a comprehensive risk assessment is to evaluate macro-risks (geopolitical and financial), resilience and then execute an industry/company-specific supplier self-assessment. This self-assessment should address a wide-scope of risk parameters and should test the supplier’s engagement in multiple dimensions.

This is where we want to ask questions that are business-critical to our supplier governance structure. Why? Because Self-Assessment questions are a vital form of communicating desired behavior to a supplier.

Supplier Audits (Desktop Audits or On-Site)

Supplier Audits, whether it be a desktop audit or an on-site audit (product, production, ISO, CoC etc.), serve as a follow-up — correctional activity — in order to ensure compliance and implementation levels from the previous risk assessment.

Audits will be instrumental in cementing strategic partnerships with your top-performing suppliers. They will also serve as a benchmarking tool, so you know which suppliers aren’t conforming to your terms and agreements. Audits also will serve as a basis for setting corrective actions for suppliers.

Supplier Performance Evaluations

Supplier Performance Evaluations are the best way to turn supplier relationship management into a business-critical function.

Working systematically with SPE allows your procurement organization to better define the acceptance criteria for levels for high-performing suppliers, further cementing supplier-performance KPIs, and aligning your team behind them.

Supplier performance evaluations will often — if not always — require the qualitative assessment of an internal stakeholder; the individual (category manager, strategic buyer, project manager etc.) responsible for a particular supplier, or grouping of suppliers. However, a further defined KPI mapping will allow your team to know what data to look for in your existing business solutions to make educated evaluations of supplier performance.

Data Matters

In all three of the above SRM and SPM processes, your procurement team should look to the support of digital solutions.

Implementing a solution to aid you in assessments, audits, and evaluations will allow you to gather valuable data sets about your suppliers. This data will serve as the insight to further develop and manage supplier relationships based upon empirical and historical knowledge.

IBM’s Marketing Cloud reported in 2017, “ 90% of the data in the world today has been created in the last two years alone […]”. (IBM) This is an indication that most business functions have been, and still are, incredibly negligent to the importance of having data to work with. Digitalizing within the SRM and SPM focuses will ensure that you’re gathering data and insights into your suppliers, and begin to utilize the existing supply chain data you have (ERP data) to support, cross-reference with, and/or draw correlations from those insights.

This is the true essence of data-driven decision making and strategic sourcing in 2019.

Read more about world-class Supplier Data Management here.

Supplier Risk Areas

Look at Supplier Risk and the assessment of that risk as a hygienic factor.

You brush your teeth before you go to bed, and when you wake up in the morning. You brush your teeth again before you head to work. Why? Because it’s what we do as participants in modern society; we keep things clean and maintain personal hygiene.

This is a similar outlook you need to have for supplier risk assessment and the management of that risk. It’s the first step before leaving the door every morning. It’s the key to starting your day (or buyer-supplier collaboration) on the right foot.

Below are various areas, or parameters, in which you should be assessing supplier risk in RFIs, RFPs, self-assessments, and audits:

Resilience

This is directly tied to the suppliers geopolitical and geo-financial risk profile. Resilience is typically defined as macro-risks and is sometimes out of the supplier’s control, but can be understood by an SCM team by determining how likely a supplier is to avoid or recover from the risks that they are consequently prone to.

Some ways to gauge the resilience of a supplier is:

- Look at macro indexes within various fields, tied to social, environmental and financial impacts

- Find out the risk on a country level

- Ability to recover from disaster: financial or natural (Evaluate the infrastructure)

Social Impact

There are various parameters in which you should be evaluating your suppliers’ social impact to enhance your supply chain ESG & sustainability.

Some very practical parameters to address are:

- HSEQ (Health, Safety, Environment, and Quality): Working Conditions

- Labor and Worker Rights: Worker Involvement, Rights of Freedom, Precarious Employment, Bonded Labor, Working Hours

- Child Rights and Child Labor

- Business Ethics and Anticorruption

- Impact upon Local Communities

Environmental Impact

In alignment with people and profitability, one should always be protecting the planet. That protection extends to assessing the risk at a supplier-level for environmental impact.

Some areas to gauge supplier impact on the environment are:

- Waste: Energy, Water

- Emissions: GHG, CO2, Air & Water Pollution

Financial Stability

A supplier’s financial status will be a big indicator as to how risky they are to collaborate with/how reliant they are to follow agreement terms upon quality, quantity, price, and delivery.

You should gather an understanding of their financial stability in the following areas:

- Credit Score

- Liquidity

- Profitability

- Probability of Default

- Credit Limit

Management Systems

You can’t always ensure that your suppliers’ business practices are in tip-top compliance with your organization’s values and requirements, but you can ask for them to be certified by international standards. The beauty of checking for certifications is that they’re distributed by accredited certification bodies that are — 99.9% of the time — trustworthy assessors of acceptable business practices and management systems.

Certifications of management systems are certainly industry-specific, but there are a few that pretty much all suppliers should have:

- ISO 9001: Quality Management Certification

- ISO 14001: Environmental Management Certification

- OHSAS 18001: Occupational Health and Safety Management Certification

Supplier Performance Areas

Defining standardized parameters for evaluating supplier performance will help your procurement team with goal setting, and help you to leverage supplier performance that meets your business-critical KPIs, and impacts top-line value.

As stated before, it’s important to utilize/source data from multiple business solutions in order to ensure that you’re able to evaluate a holistic picture of the supplier’s overall performance. This is best done when you can evaluate data sets that are directly correlated to the defined performance areas. (See examples below)

Evaluating supplier performance in a systematic way will allow your team to work in an agile framework of decision-making, leveraging real performance results in order to know where to allocate spend, where to red flag suppliers and when you need to cut suppliers loose.

Like Santa Claus on the night of December 24th, I’ve landed on the roof of this blog and would like to shower you with the joy of presents; in the form of supplier performance areas that you can start to evaluate. (Side Note: Imagine a 5-year-old’s reaction if they unwrapped this blog on Christmas morning… One word: Disappointment)

Some critical areas of focus in your evaluation of supplier performance are (but are not limited to):

Quality & Supply Chain

Within supplier quality and supply chain performance, you will start to gain an understanding for the quality of product and production, and understand the suppliers’ ability to perform in line with contractual agreement/agreed upon terms for the collaboration.

Some areas to draw conclusions regarding a suppliers’ performance in quality and supply chain are:

- PPM — Parts Per Million

- Complaints — Issued by your team or customers as a result of a supplier’s quality

- OTD — On-Time Delivery

- Lead Time — Is it improving, getting worse, or just staying the same??

- Delivering Upon Agreement Terms

- ASN Accuracy — Advanced Shipping Notice (logisticsbureau.com 2016)

- Quantity Ordered vs. Received — Are you getting what you agreed upon?

Commerciality

The commerciality and competitiveness of a supplier’s price point will be a good indication of what the overall costs will result in for the buying organization.

Some parameters you should look to gauge are:

- Price point — How competitive is the cost?

- Market — What’s the market standard and what’s the supplier’s market presence?

- Value-added vs. Cost of collaboration

- Cruciality of products and service to your own bottom line

Proactivity

Proactivity will serve as a performance area that can shed light upon a suppliers engagement in the buyer-supplier collaboration. This will be crucial to evaluate in strategic supplier partnerships, as the supplier — too — should be looking to form a long-term relationship.

Some areas to evaluate proactivity are:

- Ability to comply with governance structure and standards

- Collaborativeness throughout the agreement

- Suppliers’ focus on creating shared value/value-added

- Customer Service (Overall experience as a customer)

Innovation

Are you giving your suppliers the room they need to innovate?

Suppliers are a great source of innovation, creating market competitiveness for your bottom-line. Ensure that you’re evaluating suppliers ability to innovate, and give those suppliers — that have an ability to create supplier-enabled innovation — the room to do so!

Some areas to be able to evaluate a supplier’s innovative capacity are:

- Overall Competency

- Specialty or Niched offerings

- Innovation in product offerings during the duration of the relationship

- Development projects

- Technological Capability and Capacity

Explore how Kodiak Hub's end-to-end SRM platform can drive Supplier Collaboration & Innovation here.

Conclusion

There you have it.

A wardrobe filled with shiny new garments, ready to be shown off to the rest of your procurement organization.

Don’t let the classic barriers and concerns about the quality of data, lack of importance on SRM & SPM, lack of technology, fear of change, or inability to align behind KPIs dissuade you from your efforts to enhance supplier risk and performance management. You got this!

Now…

Do you dare to be the champion of Supplier Risk and Performance?

Until next time.