TL;DR

“Supplier information management” (SIM)—also known as vendor information management—is how procurement builds a single, trusted source of supplier truth across onboarding, compliance, risk, and performance. Do it well and you shorten cycle times, reduce risk exposure, and unlock better sourcing decisions. Do it poorly and even the smartest AI or analytics will steer you wrong.

This refreshed guide explains what SIM is, why it matters now, the core capabilities you need, how to implement it (without chaos), and what KPIs to track - plus contains answers to questions which buyers usually ask.

What is Supplier Information Management (Vendor Information Management)?

Supplier Information Management (SIM) is the structured process of collecting, validating, governing, and continuously maintaining supplier master data and documents—covering identities, capabilities, certifications, compliance artefacts, financial health, and ongoing performance. In practical terms, SIM creates a single source of truth that powers supplier onboarding, due diligence, sourcing, contract handoffs, audits, and performance reviews.

Put simply: if your supplier data is fragmented, every downstream process (from RFx to audits) inherits that noise. Independent research consistently shows that poor data quality degrades decision-making and AI outcomes in procurement. (Deloitte)

Why SIM Matters Right Now

-

Compliance pressure is climbing. New rules like the EU Corporate Sustainability Due Diligence Directive (CSDDD) require systematic supplier due diligence and documentation. That’s impossible without disciplined SIM. (European Commission)

-

Digital procurement ROI depends on clean data. Organizations are investing in adjacent capabilities (e.g., CLM, SRM); they only pay back when supplier data is trustworthy and portable. (PwC)

-

Procurement’s role is expanding. Boards expect savings and resilience and ESG progress. A mature SIM foundation makes those targets compatible, not conflicting. (McKinsey & Company)

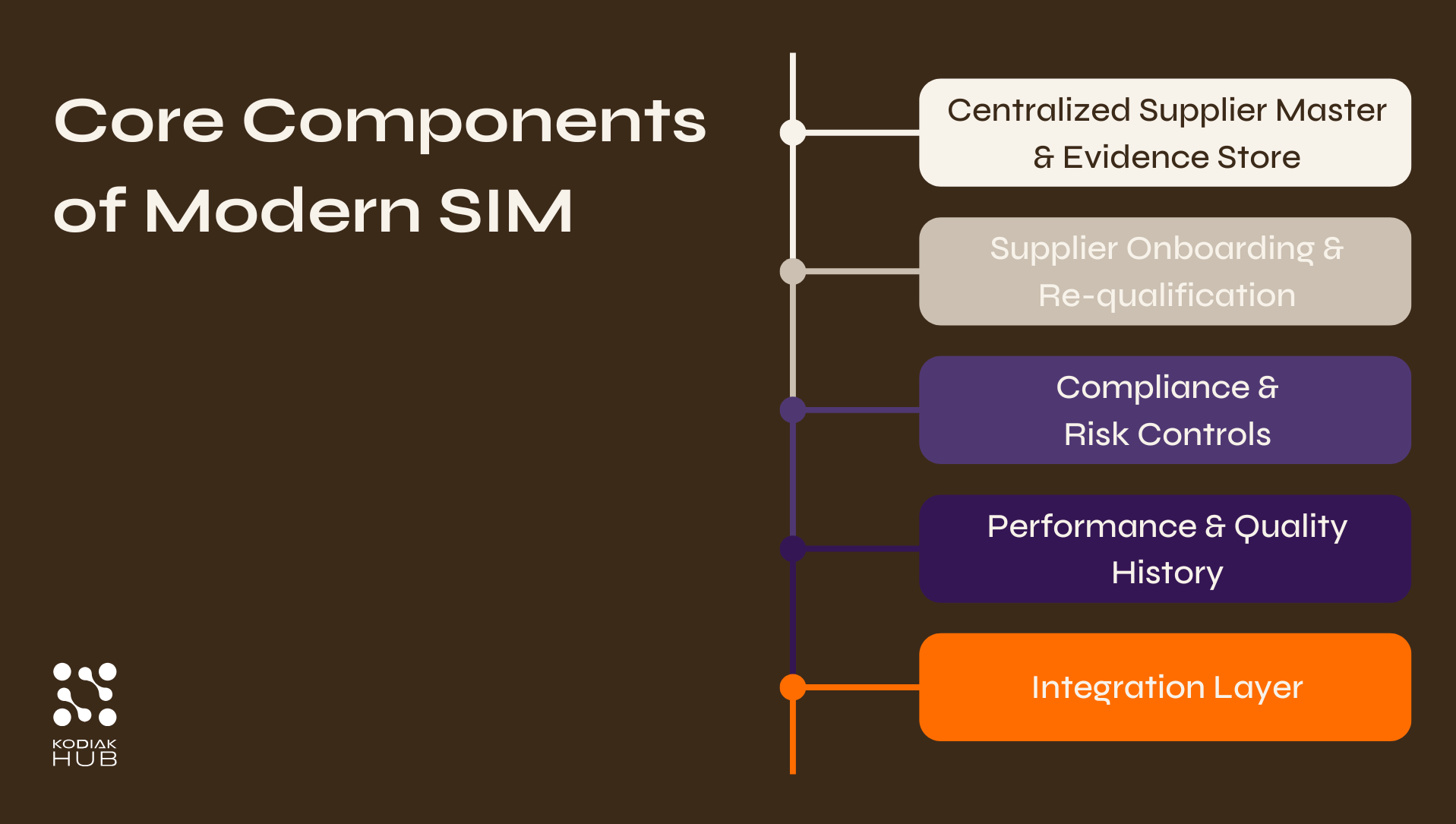

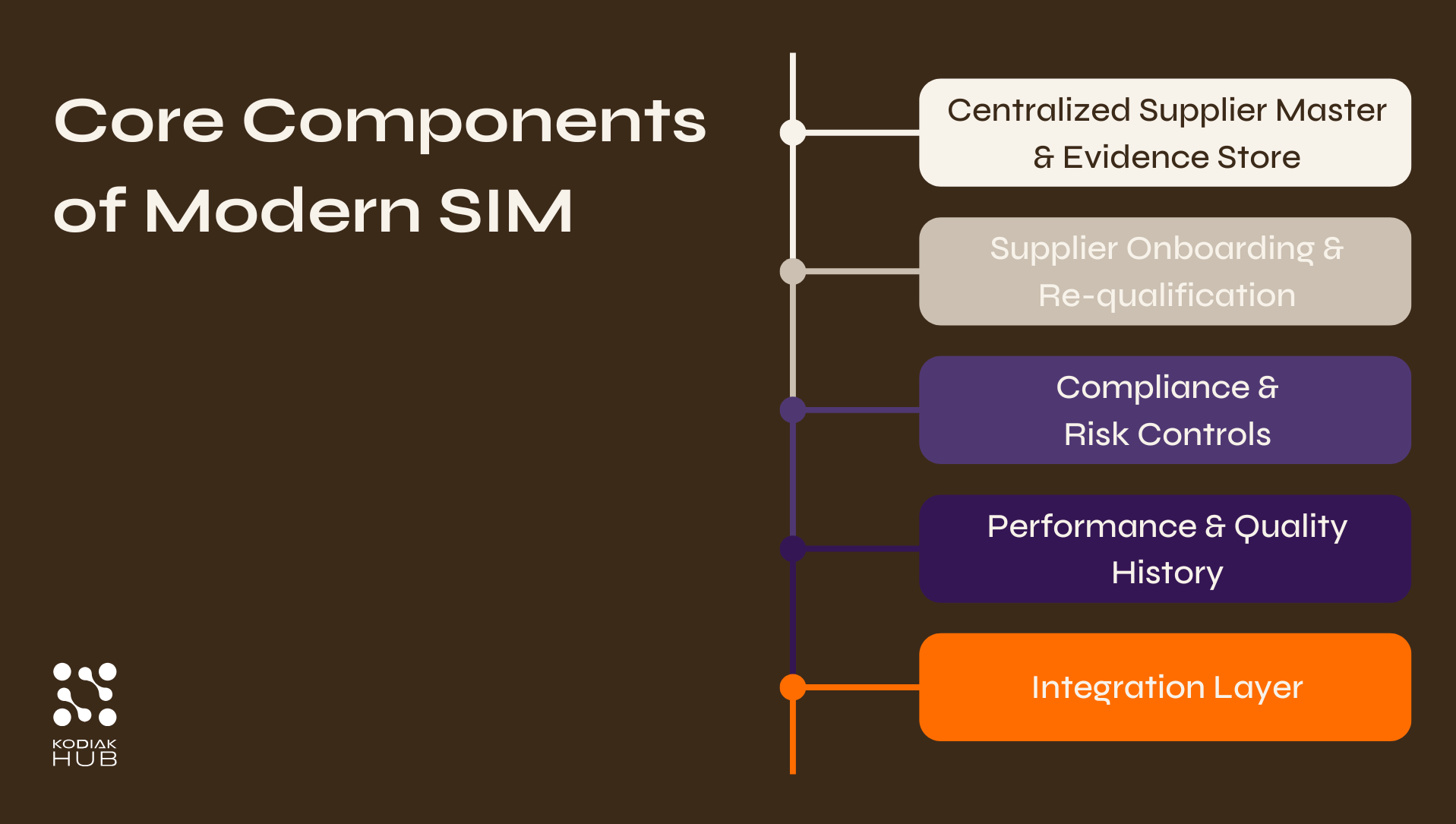

Core Components of Modern SIM

1) Centralized Supplier Master & Evidence Store

A governed database for IDs, banking/tax info, categories, site locations, capacity, certifications & compliance documents, insurances, and scorecards—plus timestamps, ownership, and audit trails. Check our guide on consolidating supplier data.

2) Supplier Onboarding & Re-qualification

Orchestrated workflows with validations (VAT, D-U-N-S, sanctions), configurable questionnaires by category/region, and self-service supplier portals. Re-qualification cycles keep data fresh. Learn more about supplier onboarding software.

3) Compliance & Risk Controls

Policy-aware checks for regulatory frameworks (e.g., environment, labor, product safety), plus automated reminders for expiries (ISO 9001, ISO 14001, IATF, GxP). Connect SIM to risk scoring and incident management so material changes trigger reviews. Learn more about supplier compliance and risk management.

4) Performance & Quality History

Integrate delivery/OTIF, non-conformances, corrective action plans, audit findings, and QBR notes. Use SIM as the backbone that links sourcing decisions with real-world outcomes. Read more about supplier performance management software.

5) Integration Layer

Open APIs to ERP, PLM, finance, CLM, and analytics platforms—plus SSO/SCIM and fine-grained permissions. Read more about supplier data integrations here.

Benefits of Supplier Information Management (SIM)

-

Faster sourcing & onboarding: pre-qualified data cuts RFx setup and vendor cycle time.

-

Lower compliance risk: live document status and systematic due diligence simplify audits and reduce penalties. (CSDDD and similar frameworks expect structured supplier records.) (European Commission)

-

Better negotiations: clean supplier masters + performance histories = credible benchmarks in QBRs.

-

AI that actually works: high-quality supplier data underpins predictive models (risk, should-cost, ESG), avoiding garbage-in/garbage-out. (Deloitte)

-

Measurable transformation impact: organizations with strong procurement data foundations realize more of their digital program’s value. (McKinsey & Company)

SIM vs. SRM vs. “Vendor Information Management”

-

SIM = the data layer & governance: onboarding, validations, evidence, lifecycle maintenance.

-

SRM = the relationship & performance layer: collaboration, scorecards, QBRs, improvement plans, innovation funnels. Read more about Supplier Relationship Management.

-

Vendor Information Management is often used interchangeably with SIM - just ensure your scope covers both master data and compliance artefacts. Learn more about supplier information management software here.

Implementation: A Practical, Low-Drama Plan

Step 1: Establish Data Governance

Define owners (procurement, quality, compliance), naming conventions, required fields by category/region, and escalation rules. (This is where many SIM projects succeed or fail.)

Step 2: Start with a “Critical 100” Suppliers Cut

Clean the fields you use every week (IDs, banking, tax, certificates, risk flags). Don’t boil the ocean—prove value with your most material suppliers first.

Step 3: Digitize Onboarding & Re-qualification

Automate requests and validations, map dependencies (e.g., ISO 9001 for critical items), and set renewal cadences. ISO 9001 frameworks emphasize consistent supplier evaluation and evidence—codify those expectations in SIM. (Advisera)

Step 4: Integrate for Flow, Not Just Storage

Push/pull to ERP (payables), CLM (obligations), sourcing (RFx templates), and BI (metrics). Learn more about The best SRM Software providers

Step 5: Train, Measure, Iterate

Make SIM part of the daily workflow: QBRs, audits, sourcing events. Review data-quality KPIs monthly and close the loop with suppliers. Top programs align training and change management to realize digital value. (PwC)