In the competitive world of Procurement and Sourcing, identifying the right suppliers is critical to business success. A thorough vendor assessment can ensure your supply chain operates smoothly while aligning with your organizational goals. This guide will walk you through what vendor assessment is, its importance, key areas to focus on, and tips for effective supplier evaluation.

What is Vendor Assessment?

Vendor assessment is a systematic process to evaluate and analyze potential or existing suppliers based on predefined criteria, such as their capability, reliability, and operational practices. This ensures they meet your company's standards for quality, compliance, and overall supplier performance. The process involves gathering data, scoring suppliers, and determining their suitability for long-term partnerships to ensure alignment with an organization's needs, values, and strategic objectives..

Importance of Supplier Assessment

Vendor assessment is more than just a box-checking exercise—it’s a strategic move to secure your supply chain and foster sustainable partnerships. Here’s why it’s critical:

- Risk Mitigation: Identifying potential supplier risks, such as supply chain disruptions or compliance issues, before they impact your operations.

- Cost Efficiency: Partnering with reliable suppliers reduces operational inefficiencies and unexpected costs.

- Strategic Alignment: Ensures suppliers align with your organization’s ethical, sustainability, and operational values and your long-term strategic sourcing and procurement goals.

Key Areas within Vendor Assessment

Vendor assessment isn't one-size-fits-all. Focusing on these key areas will give you a comprehensive evaluation to make informed decisions about which suppliers to partner with:

- Supplier Quality: Assess the supplier’s ability to deliver high-quality goods or services consistently, as maintaining consistent quality standards impacts the reliability of your operations. Check certifications, production processes, and customer feedback as well as defect rates and adherence to quality control.

- ESG Practices: Environmental, Social, and Governance (ESG) compliance is now a major factor in vendor assessment, both to comply with new regulations and to meet customer and shareholder sustainability expectations. Assess how suppliers contribute to sustainability, uphold ethical labor practices, and adhere to environmental regulations.

- Supplier Diversity: Supplier diversity isn’t just a good PR move—it drives innovation and broadens perspectives. Working with diverse suppliers—such as minority-owned or women-owned businesses—can enhance innovation and align with corporate social responsibility (CSR) goals. Evaluate efforts to include diverse suppliers or those certified as minority-owned businesses.

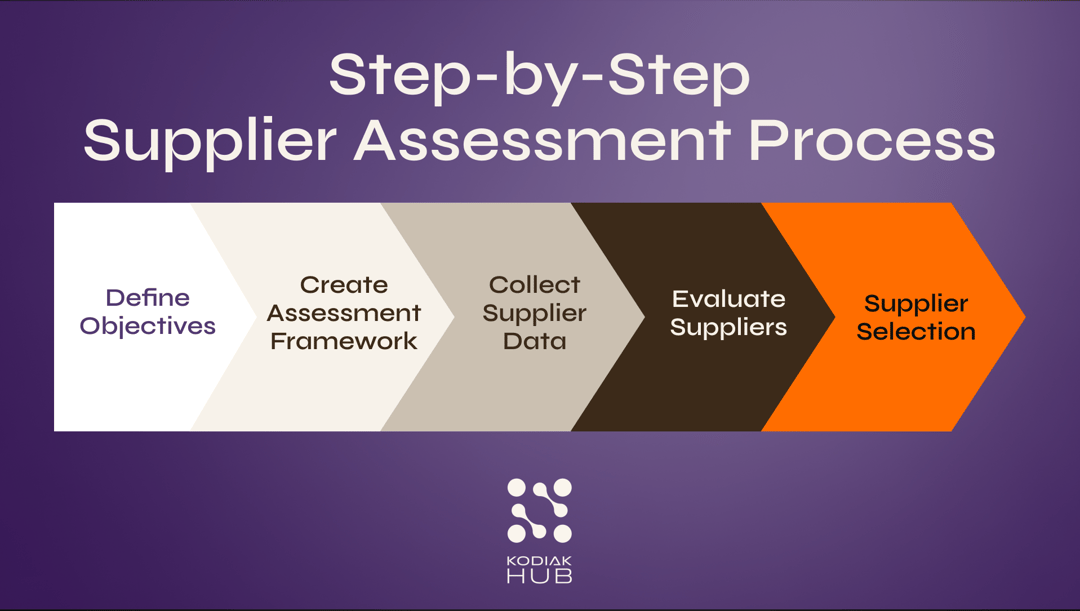

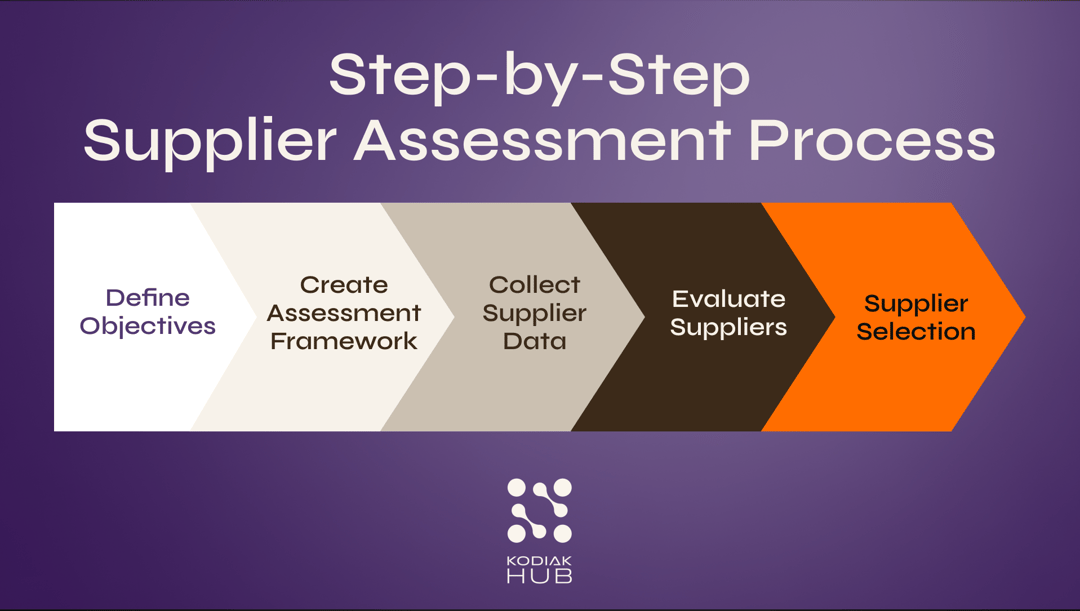

Supplier Assessment Procedure

Here is a step-by-step approach to ensure a fair and objective assessment process of potential or existing suppliers.

Steps in Supplier Assessment Process

- Define Objectives: Clearly outline what you aim to achieve through the assessment (e.g., cost-efficiency, quality, or compliance)—whether it's identifying a new supplier or reassessing an existing one.

- Create an Assessment Framework: Develop a scoring system based on criteria like quality, compliance, delivery times, and pricing to narrow down your supplier candidates to those with the best fit.

- Collect Supplier Data: Gather information through supplier questionnaires, surveys, site visits, audits, or third-party evaluations to gain a holistic picture of your potential or existing supplier’s performance. The supplier information that you collect can be either internal, external, or both–and should include both qualitative and quantitative supplier data.

- Evaluate Suppliers: Create robust supplier scorecards that give a holistic view of the supplier so you can effectively score and rank suppliers against your framework with clear benchmarks and KPIs.

- Supplier Selection: Select suppliers who meet or exceed your standards and best align with your organization’s goals. By leveraging new technology powered by automation and advanced analytics, such as an SRM system, you can boost efficiency and unlock valuable insights that empower your organization to make smarter sourcing decisions.

Key Criteria to Evaluate Suppliers

When assessing suppliers, focus on criteria that impact your business outcomes:

Best Practices When Creating Vendor Assessment Questionnaires

Vendor assessment questionnaires are invaluable for collecting consistent and comparable data, and crafting effective questionnaires is a cornerstone of vendor assessment. Here’s some best practices that you should follow in your supplier assessments:

5 Tips for Successful Supplier Evaluation

- Build a Long-Term Strategic View: Assess suppliers for their long-term potential, not just their immediate performance.

- Collaborate with Stakeholders: Involve cross-functional teams to get a holistic view of supplier performance.

- Regularly Monitor Supplier Performance: Continuously monitor supplier performance to ensure they maintain standards on quality, delivery, cost, sustainable practices, etc..

- Use Supplier Scorecards: Develop supplier scorecards to provide a standardized evaluation format.

- Invest in Technology: Utilize Supplier Relationship Management (SRM) tools to simplify and enhance the evaluation process.

Conclusion

An effective vendor assessment process is vital for finding and maintaining partnerships with the best suppliers. By focusing on quality, ESG practices, diversity, and structured procedures, you can align your procurement strategy with organizational goals. Use the tips and best practices outlined in this guide to streamline your process and build a resilient, efficient supply chain.