It’s never a bad decision to weigh the pros and cons of your organization’s strategies and activities.

Improving within a function is a continuous uphill battle and – sometimes – the easiest way to develop and innovate is to review the basics, and also to educate your team of potential pitfalls.

Procurement is a domain undergoing exponential change, caused mainly by digitalization and organization/customer demands. Your team is clawing at every opportunity to stay one step ahead of your competition and leverage your suppliers and supply chain activities to show your C-Suite that procurement is to be taken seriously as a value adder.

Kodiak Hub sees the need for procurement professionals to continuously develop in this era of great change, and we’ve put together a checklist to help.

17 Do's & Don'ts for Procurement

1. DO: Streamline Contracts

Procure-to-Pay (P2P) and Source-to-Pay (S2P) have become key focuses for procurement teams looking to eliminate traditional procurement activities, rooted within manual processes and paper trails.

“A traditional procurement process is characterized by manual events, including many small, repetitive tasks. These tasks could be anything from approvals, writing RFxs contracts, negotiations and discussions of bids” (Claritum).

P2P solutions of today focus on alleviating the stressors of hands-on tasks by streamlining RFIs, RFPs, RFQs, all the way through the lifecycle of the purchase, to the contract signing, transaction and then on-going contract management.

P2P solutions have been proven to reduce cycle times for placing orders, increased number of orders processed and reduced the average supplier lead time. Efficiency in the hands-on purchase makes life easier for you and your suppliers.

Working with streamlined P2P processes allows you to be agile in contracts, and allocate resources within your procurement team more effectively.

Learn more about streamlined Supplier Contract & Document Management here.

2. DO: Gather Supplier Master Data

Having a robust set of supplier master data is a pivotal element of working with suppliers more strategically and feeding that data into new solutions.

Data is a hygiene factor that you need to make you’re keeping clean when it comes to suppliers, and you need to do so within various parameters (contact, financial, performance, quality, sustainability, compliance). If you don’t know your suppliers contact information, how are you going to ensure that they’re financially stable or bearing the correct international certifications?

Read our blog post on modern Supplier Master Data Management to learn more.

3. DO: Source Responsibly & Strategically

Now that your supplier data is clean, let’s start using it to source more strategically, and responsibly!

Increased globalization and stakeholder pressures on responsible/sustainable business practices have created a new risk reality for the global supply chain. Responsible and strategic sourcing are business disciplines that have inherently become more business critical for enhancing top-line and brand value.

Gathering environmental, social and financial information regarding supplier performance is a KPI to good supplier collaboration. One of the main methods for gathering supplier data is to send self-assessments. You should set the scope of your self-assessment to focus on various sustainability and CSR aspects, which can be utilized to make strategic decisions about future supplier collaborations. This is an easy way to start actualizing responsible sourcing practices.

The responsibility of sourcing is a shared responsibility; a responsibility that must be governed, complied with, expected, standardized, and executed upon by suppliers, traders, manufacturers, logistics providers, purchasers, retailers, investors, employees, and consumers, alike!

Read more about how to empower Responsible Sourcing and ESG & Sustainability throughout your supply chain.

4. DO: Supplier Governance

If you’ve taken the time to gather information about your supplier’s activities, and they seem to be compliant with your supplier CoC, it's time to check the implementation levels of that compliance.

Auditing is a great way to govern suppliers, ensuring that they’re continuing to function as an asset to your organization, and a direct way to evaluate supply chain risk areas.

Brand value is directly aligned with the performance of your suppliers and supply chain, and governing suppliers best safeguards brand. There’s no way to ensure on-site activities are up to par with your organization’s expectations without visiting suppliers on-site.

5. DO: Supplier Development Programs

Chartered Institute of Procurement and Supply’s definition of Supplier Development is: “closely related to supplier relationship management and is the process of working with certain suppliers on a one-to-one basis to improve their performance for the benefit of the buying organization” (CIPS).

An element missing from CIPS definition is the idea of mutual gain from supplier development. Suppliers undergoing a development program typically have elements of their production or organization to improve upon. A supplier development program, thereby, builds value for not only the buyer but supplier as well; making them a more attractive supplier for other buying entities.

While supplier relationship management is a framework for all interaction between the buyer and supplier, supplier development is a one of the means to optimize that relationship. Leveraging your supplier relationships and collaborations to locate areas for wins is a desirable end goal of strategic sourcing and supplier governance.

Some of your suppliers will be ready to form key partnerships earlier in your collaborations, whilst others will require development, training, educations and increased communication. Building a quality supplier development program can move your procurement strategy from being focused on working with reactive suppliers to collaborating with mainly strategic suppliers.

Supplier development programs allow you to further align your organization with suppliers and increase opportunities for supplier-enabled innovations.

Learn more about how to drive Improvement Projects and Supplier Quality with Kodiak Hub's SRM system.

6. DO: Clarify Procurement KPIs

The ability to gauge performance is a necessary prerequisite for forecasting future organizational success in all business areas.

When it comes to defining procurement KPIs, in the shifting business landscape, your organization needs to be agile, yet methodical.

Developing KPIs is crucial, and individual, to the infrastructure of your procurement team. KPIs can be the blueprint for success, and also the foundation for pivoting. Remember, goals drive performance, and knowing how to gauge that performance a good way to reach your goals. But, sometimes goals are unrealistic or misguiding. Gauging performance is as equally important to forging forward as it is to thinking things over.

Whatever way you cut it, developing KPIs is all about identifying value drivers, and planning to exploit those areas for organizational gain. Procurement is a means to an end, and the end is enhanced top-line value.

Some KPIs that might get the ball rolling in the right direction for your organization are:

-

Cost

-

Production Price

-

Time of Delivery

-

Spend

-

Supplier Compliance

-

Environmental Impact/Sustainability & CSR Parameters

-

Supplier Collaboration and Communication

-

Supplier Base Consolidation

-

Customer Satisfaction

-

Procurement ROI

Discover how Kodiak Hub's end-to-end SRM system can empower your organization to succeed with its Goals & Procurement Strategy.

7. DO: Supplier Performance Evaluation

Just as your organization would do within any other partnership, your procurement team should be making decisions within the supplier base, based on performance and quality.

Approaching supplier performance management with clearly defined KPIs and goals is important, and KPIs should be communicated to suppliers, and continuously evaluated. Gaining supplier data, and focusing on supplier performance management, will allow your procurement team to locate key suppliers quicker, eliminate non-compliant suppliers, consolidate your supplier base, and create a framework for any supplier development programs.

“Incorporate appropriate service levels and metrics into agreements. A relationship based on a handshake is far more likely to encounter problems than one in which expectations are clearly established and agreed upon” (Blanchard 2009).

Quantitative measurement of performance allows you to be objective in your evaluation of supplier performance. Qualitative activities with suppliers, that are business critical (collaboration, compliance, innovation), should also be quantified within a supplier performance scorecard so your team can evaluate performance over time and categories.

Some of these elements for more qualitative evaluation will require that your team gather data from various stakeholders or solutions (procurement managers, suppliers, sustainability experts, ERP data). Gathering more robust data sets within various scopes allows your organization to create more comprehensive performance scores for suppliers.

8. DO: Focus on Category Management

“Many organizations have looked to the strategic development of supplier categories to align procurement efforts with business goals and provide value to the enterprise” (Spend Matters 2015).

An organization that boasts a clearly defined category infrastructure will have an easier time scaling their product innovation, collaborating with suppliers, reducing costs, reducing lead times, and increasing customer satisfaction.

Category Management can aid your organization to work with a more strategic approach within your procurement, allowing your stakeholders to focus on creating shared value rather than ad-hoc price reductions.

The best part about having a strong focus on category-based procurement is that if you do need to be reactive within a supplier relationship than you’ll have an easier time to do so because you’ll have an internal stakeholder designated to the product category or supplier.

9. DO: Identify Customer Needs & Evaluate Customer Satisfaction

‘"The customer is always right."

This often-said notion is branded into the minds of procurement professionals worldwide.

Customer satisfaction is a strong indication of how successful your procurement organization is functioning. While procurement has the opportunity to introduce new products and innovative solutions to customers/stakeholders, it also has an obligation to the brand – and brand ambassadors – to uphold quality for existing products.

Your procurement team needs to identify customer needs and continuously evaluate satisfaction, in order to ensure you’re meeting the market at the front door.

In an example from The six fundamentals of procurement, Mathew Sparkes, head of financial services at the Crown Commercial Service (CCS), illustrates the importance of identifying customer needs.

“Using the example of Heathrow’s Terminal 5, Sparkes said the airport originally wanted “rows and rows of check-in desks”. The procurement team identified the real need wasn’t having enough desks, it was moving footfall quickly through the terminal. Armed with this understanding, Sparkes said the procurement team suggested an alternative solution based on supermarket checkouts, reducing both check-in times and costs” (Churchill 2017).

By identifying customer wants and needs, the procurement team was able to locate an area for a win and allocate their resources correctly.

10. DO: Look Outside Your Market

Understanding where your procurement organization stands, in comparison to competitors is important, but comparison across industries is equally as useful.

Benchmarking across industry sector can prove to create innovative solutions within a procurement organization.

Industries like chemicals and/or automotive, have much more demand for efficiency in their procurement by internal and external stakeholders. For this reason, these industry sectors are typically more structured and innovative in their procurement organizations. For a much lower risk supply chain, such as telecommunications or real estate, there could be a lot of lessons to be learned.

Look for procurement meet-ups in your area to stay in contact with leaders in other business sectors, and stay ahead of coming trends. One of the main learnings you’ll be able to take away from more innovative procurement teams is what technology their using, and how it’s making their activities/strategies more efficient.

11. DON'T: Adopt Technology You’re Not Ready For

Blockchain this, AI that, RPA who?...

Emerging technologies are forming dangerous buzzword trends that could be blinding your procurement team from the real work at hand. Your procurement team should be focused on data compilation, scalability and growing more complex analytics.

Regardless of the noise, the mainstream market isn't-yet-mature enough for the likes of large-scale AI, Blockchain and RPA adoption. Developing more quality data sets will allow your procurement team to adopt future technologies when they reach maturity.

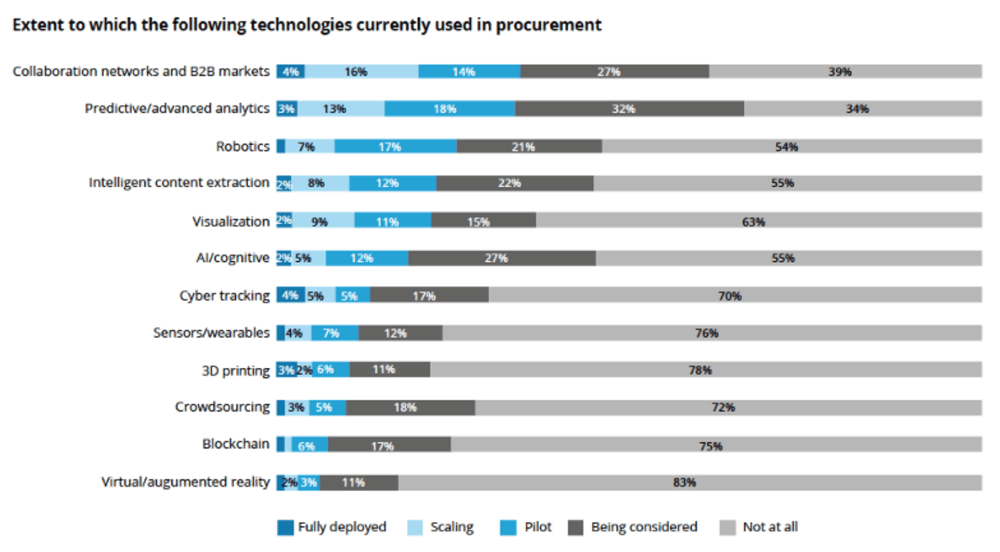

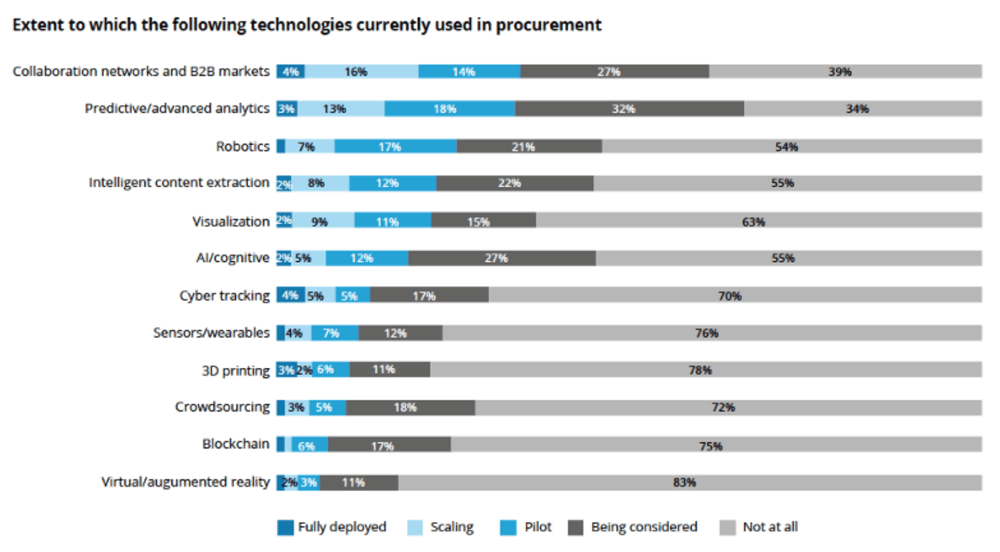

Though the headlines say one thing, this is what the Deloitte CPO Survey has to say about current technologies being used in procurement. Puung focus on analytics and collaboration networks with suppliers are the most reasonable focuses, as per the survey. Certain industries/organizations will be ahead of others in their technological competencies, but building a foundation for streamlined digital procurement should be the main focus. Don’t go adopting technology you’re not ready for.

12. DON'T: Focus Solely on Price

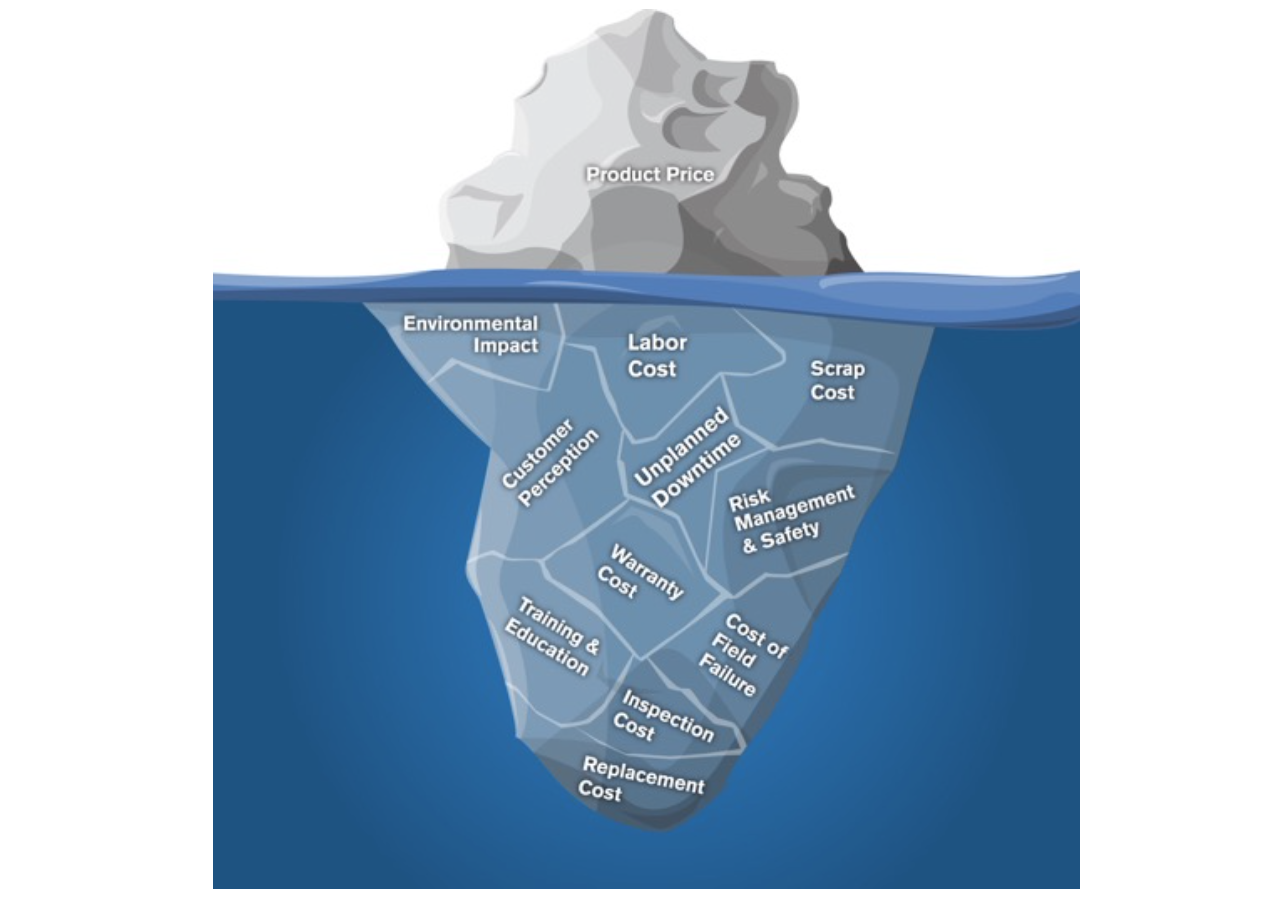

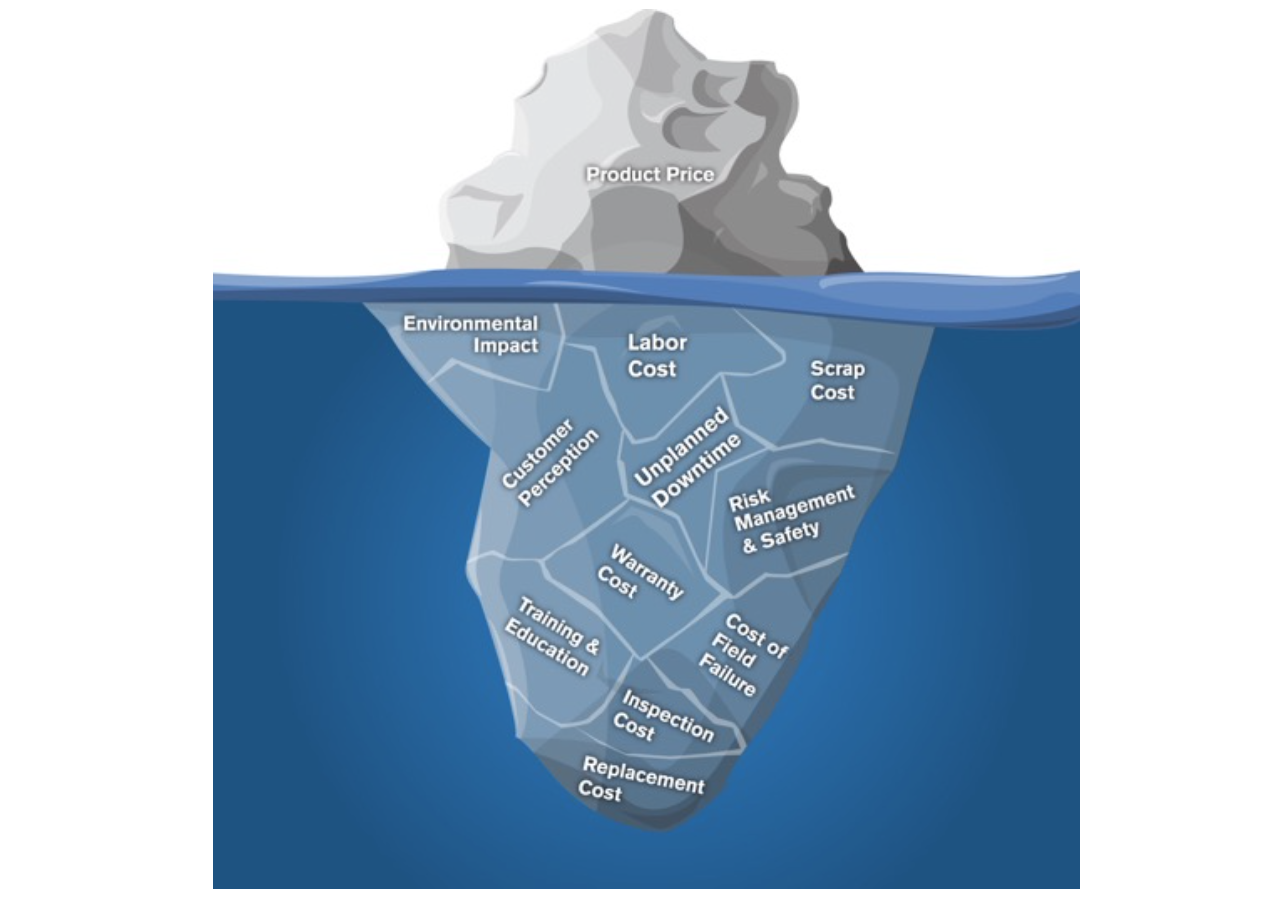

Instead of focusing solely on the price point of a product or service, you should be focusing on gaining an understanding of the Total Cost of Ownership (TCO). From here, you can locate areas where you can start to reduce the TCO.

The common model to illustrate the importance of calculating TCO is the Iceberg model. The product price is visible to a procurement professional, but what about the hidden costs that come along the way with a supplier collaboration; not only tied to monetary costs, but social and environmental implications as well?

“For large spend areas, teams from companies that run procurement well are abandoning the outdated practice of receiving multiple bids and selecting a supplier simply on price. Instead, they consider many other factors that affect the total cost of ownership such as operating costs, training, maintenance, warehousing etc.” (Koble 2017).

Focus on procuring materials, products, and services from suppliers that you can develop a more comprehensive understanding of the end price or the TCO.

13. DON'T: Treat Suppliers Like Vendors

Suppliers are a great source of potential strategic partnerships and product innovation. Treating your suppliers like one-off vendors isn’t the right approach for building shared value through procurement.

If you’re looking to work strategically with suppliers, you need to ensure that there is a mutual engagement in the relationship, and you need to put trust in your supplier competencies.

Your suppliers are experts in their fields. Communicate with your key suppliers, and encourage them to create supplier-enabled innovation, because – in most cases – they are more than capable of doing so.

If your supplier is running a production run, and sees an opportunity to cut costs, innovate within the manufacturing of a commodity, create a complimentary/new product, or something similar, encourage their exploration of the innovation. This is the true essence of collaborative innovation with suppliers; creating opportunities for mutual gain and added top-line value. Having close relationships with key suppliers will put your organization in line to be co-innovators, rather than the supplier choosing another partner company.

14. DON'T: Underestimate Transparency When Negotiating With Suppliers

Negotiation is a pivotal part of supplier collaborations, especially if they’re meant to become long term relationships.

Communication is vital to ensure that there is transparency in the contract. If you, or your supplier, plan to renegotiate on repeat orders, it's good to know that information from the beginning. Be methodical in the questions/principles you'd like to inquire/communicate to suppliers before the collaboration begins.

This also goes for supplier compliance being communicated during contract negotiations. Being transparent in your organization's standards, requirements and expectations can safeguard your company if any kind of legal issues arises throughout the procurement process.

One of the elements where initial communication and complete transparency is important is IP (intellectual property). If you choose to invest resources (Time or money) in a supplier-led innovation project, just make sure that there is a proper understanding of ownership. You should ensure to create legally binding joint development agreements, from the start.

Transparency requires communication and openness from both parties.

15. DON'T: Practice Rushed Purchasing

Reactive or rushed purchasing is never a scalable activity, and it won’t create long-term value for your organization, core business or your supplier relationships.

As deemed by Daniel R. Krause, in his 1998 study titled, An empirical investigation of supplier development: Reactive and strategic processes, there are two main approaches to the supplier management process:

- Reactive Approach — Where companies start managing the supplier relationships only when unpleasant situations with suppliers occur, and try to figure out how to improve the performance of unreliable suppliers.

- Strategic Approach — Where supplier relationship management starts even before an agreement with the supplier is signed, in order to ensure the competitive advantage of the company in the long run. This is a forward-focused approach, which can lead to a successful relationship even in the early stages (purchasecontrol.com 2018).

Obviously, some purchase agreements/contracts will have to be entered in times of reactive procurement, but focus on reducing these types of purchasing habits will prove profitable for your organization in the long run.

Really, you need to ask yourself: What purpose does this supplier relationship fill within our organization, and is a reactive purchase more valuable than taking the time to form a strategic partnership?

16. DON'T: Be Cheap!

As mentioned above, focusing solely on price can cause one to lose sight of the other costs involved in the procurement process.

Besides from losing track of the TCO from hidden costs of a product, service or material, you need to remember that the cheapest bid isn't always going to result in the best end result.

Quality and customer satisfaction are directly tied to choices made within tendering. Take your evaluation of bids seriously, and enter collaborations that meet a holistic list of requirements, not just price point or budget.

17. DON'T: Turn a Blind Eye to Change Management

Implementing change and managing change are no easy task, and for that very reason, change requires infrastructure, processes and clearly defined actions.

Magnus Carlsson’s book, Strategic Sourcing and Category Management: Lessons learned at IKEA, is a masterful composition and guideline of how a procurement and sourcing organization can start building a quality infrastructure by gaining inspiration from IKEA’s triumphs and failures.

After creating — in essence — the bible for strategic sourcing and category management, Carlsson dedicates the entirety of last two chapters to speak about change management and change as a function for reaching goals and building organizational value.

.png?width=720&name=Blog%20Image%20(9).png)

Carlsson utilizes John Kotter’s 8-step change model as an example for building an infrastructure for change. Utilizing this concrete, yet flexible, model for a change process allows the ability to plug-and-play, making it customizable to the specifics of an organization’s desired change project.

Utilizing Kotter’s model allows us — the dreamers of change — to ground ourselves in a solidified vision of change, identify opportunities, avoid pitfalls, maximize wins, and ultimately create organizational change leading to shies in an organization’s culture.

In this transformational era of procurement, you need to ensure that your team and organization are well positioned for change.

.png?width=720&name=Blog%20Image%20(9).png)