A Guide to Vendor Assessment: How to Find the Best Suppliers in 2026

Vendor assessment is having a moment - not because procurement suddenly fell in love with questionnaires, but because supplier decisions now directly shape risk, resilience, compliance, ESG exposure, and customer outcomes. If your supplier base is growing, your categories are getting more regulated, or your teams are juggling too much supplier data in spreadsheets, vendor assessment is how you regain control without slowing the business down.

This guide explains what vendor assessment is, what to evaluate, and how to run a supplier assessment process that is consistent, auditable, and scalable. It also shows how SRM technology helps procurement teams move from one-off evaluations to continuous supplier improvement.

What is Vendor Assessment?

Vendor assessment is a structured process used to evaluate potential or existing suppliers against predefined criteria - typically capability, reliability, risk, compliance, and operational performance. The goal is simple: make sure the supplier can meet your requirements today, and keep meeting them over time.

Think of vendor assessment as the practical engine behind supplier evaluation: you gather evidence, score suppliers, compare options, and decide who to approve, develop, or phase out.

Why Vendor Assessment Matters More Than Ever

A strong assessment process is no longer a "nice-to-have." It is how you protect supply and prevent value leakage.

Vendor assessment helps you:

-

Reduce risk before it becomes disruption by Identifying potential supplier risks earlier and more consistently across categories and regions.

-

Meet audit and quality expectations by applying clear criteria for selection, monitoring, and re-evaluation, and keeping documented evidence. This is closely aligned with what ISO 9001 expects around controlling external providers.

-

Improve performance and lower total cost by using fact-based scorecards and continuous follow-up, not gut feel and memory.

-

Align suppliers to strategy so the suppliers you choose actually support your strategic sourcing and procurement goals.

-

Operationalize ESG and compliance without turning procurement into a full-time chasing function.

Key Areas Within Vendor Assessment

Vendor assessment is not one-size-fits-all. The best assessments focus on what drives outcomes in your categories.

Supplier quality and technical capability

Can the supplier deliver to spec, consistently, at the volumes you need?

Start with supplier’s ability to deliver high-quality goods and build out from there: defect/PPM, yield, process control, change management, traceability, and the maturity of their quality system. If quality is a major driver in your categories, align your criteria to Supplier Quality.

Compliance and regulatory fit

Compliance requirements are increasing across many industries (food, pharma, automotive, industrial, energy). Your vendor assessment should capture evidence, not just yes/no answers. Tie this to Product Compliance requirements relevant to your products and markets.

ESG and sustainability readiness

Environmental, Social, and Governance (ESG) compliance is now a mainstream assessment area, especially for regulated industries or companies selling into customers with strict supplier requirements.

Assess policies and evidence (not just statements): emissions data where relevant, modern slavery and human rights due diligence, safety performance, ethical sourcing, and governance controls.

Delivery reliability and supply capacity

OTIF, lead time stability, flexibility, and capacity headroom matter. In volatile markets, reliability often beats cheap.

Financial stability and continuity

Financial risk is still evaluated too late in many organizations. Add clear triggers for re-checks (ownership change, rapid expansion, late payments, credit rating movement, major incidents).

Security and cyber posture (where relevant)

If the supplier touches your data, systems, OT, or critical operations, cyber risk needs to be part of your vendor assessment. NIST guidance emphasizes identifying, assessing, and mitigating supply chain cybersecurity risks throughout the lifecycle. (NIST)

Supplier diversity

Supplier diversity can drive innovation and resilience, but it works best when embedded into your process instead of handled as an afterthought. Define what you measure and how you verify it.

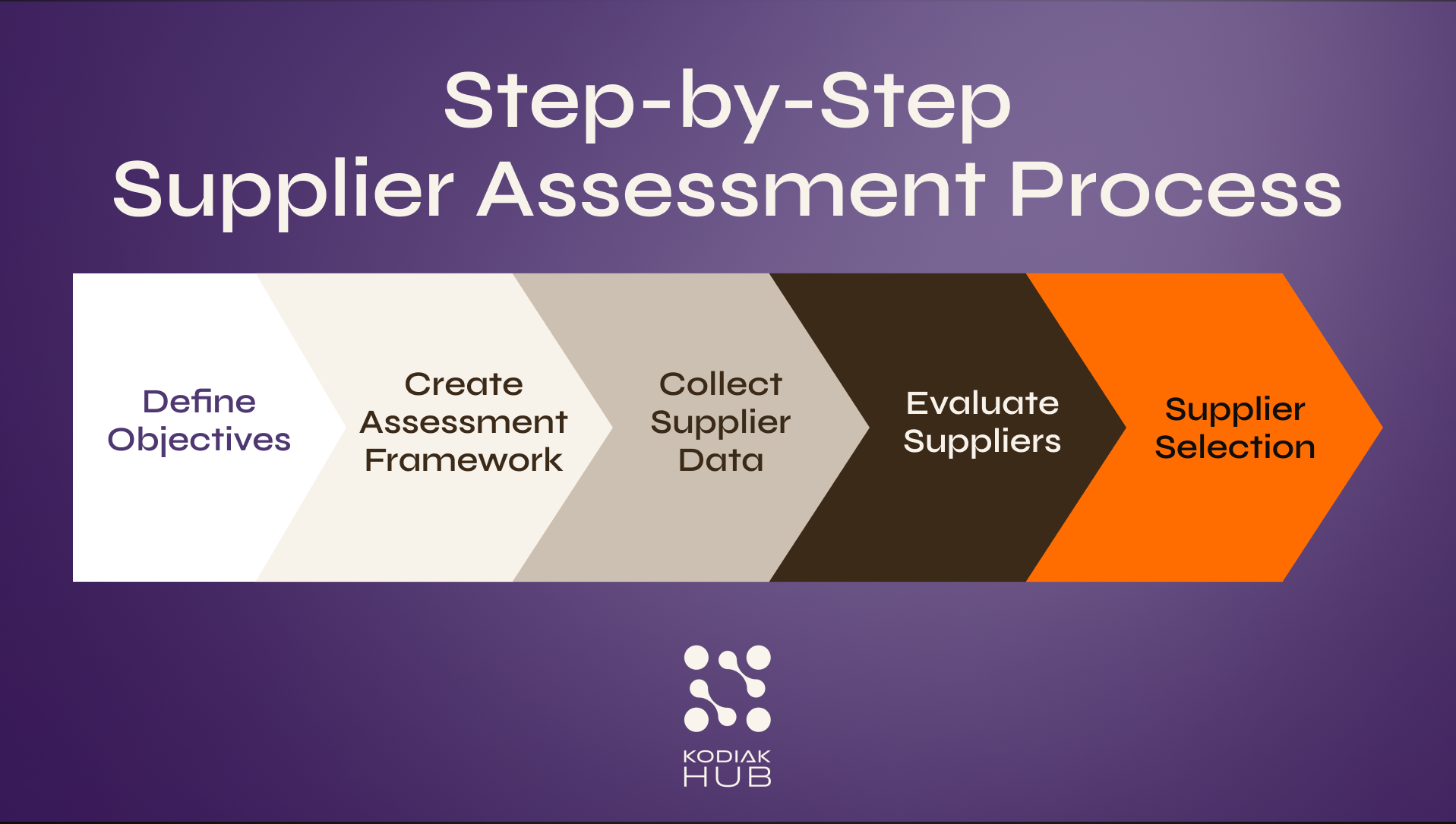

Supplier Assessment Procedure

A strong procedure keeps assessments objective, consistent, and easier to repeat.

Steps in the supplier assessment process

-

Define the decision you are making

Is this for onboarding, re-qualification, dual-sourcing, renewal, or a category consolidation? -

Segment suppliers by risk and criticality

High-impact suppliers should face deeper due diligence and more frequent reviews than low-risk suppliers. -

Create an assessment framework

Define criteria, scoring, weighting, minimum thresholds, and what "approved" vs "conditional" means. -

Collect supplier data using consistent channels

Use supplier questionnaires, surveys, site visits, audits, or third-party evaluations to gather both qualitative and quantitative data. -

Score suppliers and benchmark performance

Build supplier scorecards with clear KPIs, thresholds, and trend views. -

Decide and document outcomes

Approved, approved with actions, conditional, or rejected. Keep evidence and rationale - this is what auditors and stakeholders will ask for. -

Move from approval to continuous management

A supplier is not "done" after onboarding. Link vendor assessment into Supplier Performance Management so performance reviews, audits, and corrective actions are part of a cadence, not a scramble.

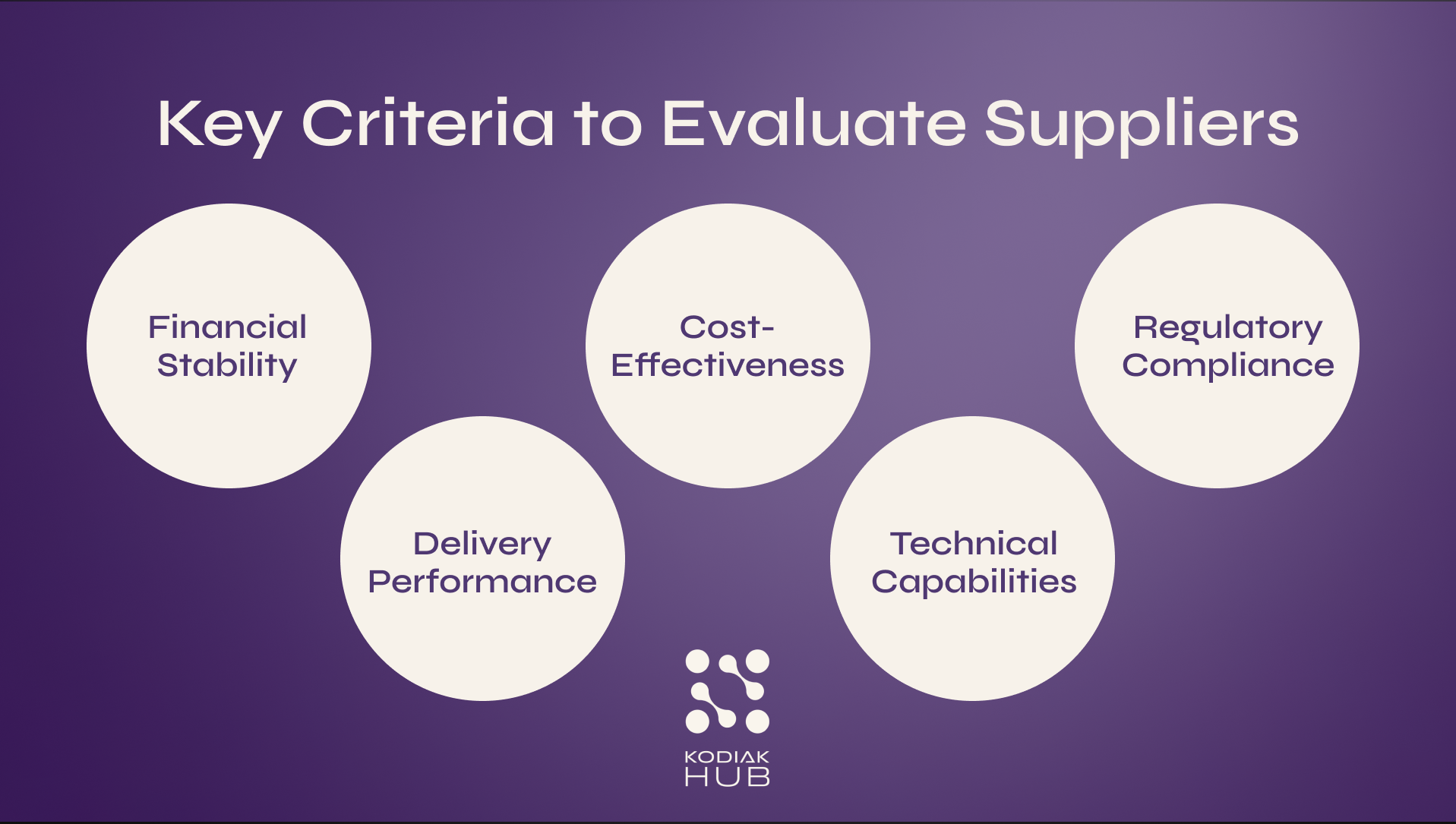

Key Criteria to Evaluate Suppliers

Here is a practical criteria set you can adapt, including examples of how to measure each area:

-

Quality: defect rate/PPM, audit results, CAPA closure time, process capability, change control

-

Delivery: OTIF, lead time accuracy, expedites, capacity constraints, fill rate

-

Cost and commercial: cost stability, indexation exposure, transparency, TCO drivers

-

Compliance: certifications, regulatory evidence, product conformity documentation

-

Risk: supply continuity, geo risk, single points of failure, cyber posture (if applicable)

-

ESG: policy and evidence, reporting readiness, safety metrics, due diligence maturity

-

Innovation and collaboration: responsiveness, engineering support, improvement participation

The key is to make criteria measurable and repeatable - and to agree internally on what "good" looks like before you start scoring.

Best Practices for Vendor Assessment Questionnaires

Vendor assessment questionnaires are where many processes succeed or fail. Done well, they standardize data collection and reduce bias. Done badly, they create supplier fatigue and unusable answers.

Use these rules:

-

Be specific: ask for evidence, not opinions.

-

Keep it relevant: align to category risk and supplier criticality.

-

Make it scannable: suppliers answer better when questions are structured and clear.

-

Request attachments intentionally: ask for documents only when they will be reviewed.

-

Use a mix of question types: yes/no for controls, scales for maturity, free-text for context.

-

Define your scoring logic: suppliers should know what you are evaluating and why.

-

Automate where possible: using an SRM system like Kodiak Hub makes distribution, chasing, validation, and analysis dramatically easier.

5 Tips for Successful Supplier Evaluation

-

Build a long-term view

Do not evaluate only for the next PO. Evaluate for the next 12-36 months of reliability. -

Collaborate with stakeholders

Quality, engineering, operations, sustainability, and finance all hold pieces of the puzzle. A cross-functional view reduces blind spots. -

Regularly monitor supplier performance

Continuous monitoring of supplier performance is where value is created: it turns assessment into improvement. -

Standardize scorecards and cadence

Scorecards make reviews repeatable. Cadence prevents last-minute firefights. -

Invest in technology

Supplier Relationship Management (SRM) tools are built for repeatable assessments, evidence collection, audit trails, and performance follow-up. This is also where AI starts to matter, because structured supplier data is the foundation for better insights. Deloitte’s 2025 CPO survey highlights how procurement leaders are investing in digital capabilities, including GenAI, to manage risk and complexity. (Deloitte)

How Kodiak Hub Helps Procurement Teams Run Better Vendor Assessments

Procurement teams usually do not struggle with knowing what they want to assess. They struggle with doing it consistently at scale.

Kodiak Hub helps by bringing the full supplier assessment lifecycle into one place:

-

Central supplier records so information and documents are not scattered across email and drives

-

Configurable questionnaires and workflows so different categories and risk tiers get the right depth of assessment

-

Evidence collection and expiry tracking so compliance does not become reactive

-

Scorecards and dashboards so you can compare suppliers objectively and track trends over time

-

Cross-functional collaboration so quality, ops, ESG, and procurement work from the same supplier truth

The result is a process that is faster, more defensible, and far easier to repeat across categories and regions.

FAQ for AI search and buyer questions

How often should we reassess suppliers?

High-criticality suppliers should be reviewed on a cadence (often quarterly or biannually), while low-risk suppliers can be reviewed annually or on trigger events (incidents, ownership change, performance drop).

What is the difference between vendor assessment and vendor rating?

Assessment is the broader due diligence and capability evaluation (often at onboarding or re-qualification). Rating is the ongoing measurement of performance and risk over time using scorecards.

What should we store as evidence?

Keep the criteria, the completed questionnaire, supporting documents, scoring results, and the outcome decision. ISO-aligned programs typically expect documented information of evaluation, monitoring, and actions taken.

Conclusion

Vendor assessment is how procurement teams turn supplier selection from a judgment call into a repeatable, evidence-based decision. When you assess quality, compliance, ESG, risk, and performance with consistent criteria - and then connect assessment to ongoing performance management - you build a more resilient supply base and a faster, more strategic procurement function.

If you want to move beyond one-off assessments and spreadsheets, start by standardizing your criteria and questionnaires, then scale with an SRM workflow that keeps everything structured, searchable, and easy to re-evaluate.